AI in Manufacturing: Predictive Maintenance Explained

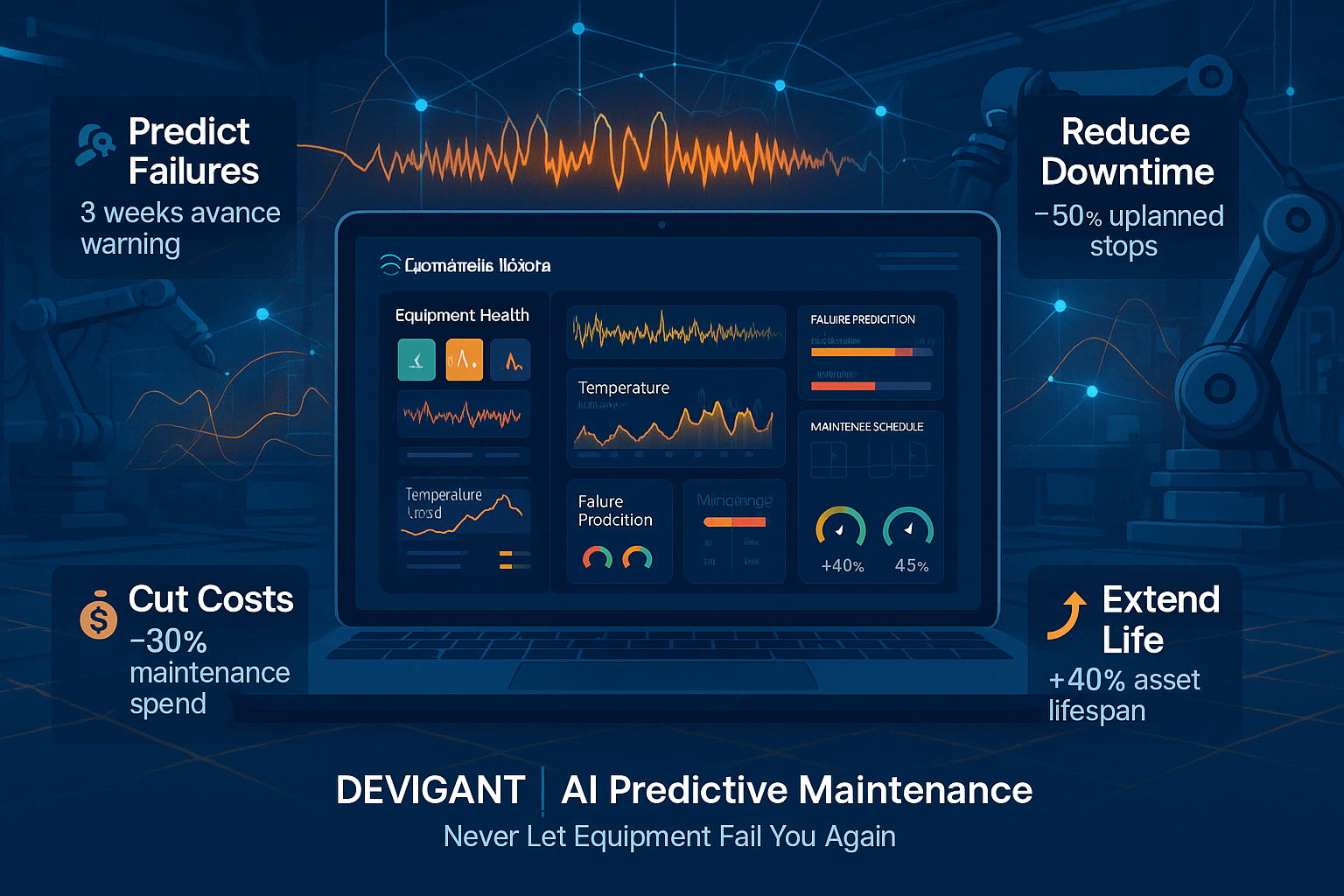

Equipment failures cost manufacturers billions annually through unplanned downtime, emergency repairs, and lost production. Traditional maintenance approaches—reactive repairs after breakdowns or scheduled maintenance based on time intervals—leave money on the table. Artificial intelligence is revolutionizing maintenance through predictive capabilities that identify problems weeks before failure, enabling planned interventions that minimize disruption while maximizing equipment life. Manufacturers implementing AI-driven predictive maintenance report downtime reductions of 40-50%, maintenance cost savings of 25-30%, and equipment lifespan extensions of 20-40%.

The Problem with Traditional Maintenance

Reactive maintenance, fixing equipment only after it fails, causes the most expensive downtime. Production stops unexpectedly, parts must be rush-ordered at premium prices, and repair crews work overtime. The total cost of unplanned downtime often exceeds planned maintenance by 3-10 times. Preventive maintenance based on fixed schedules improves reliability but wastes resources replacing components with remaining useful life while sometimes missing problems that develop between scheduled intervals. Neither approach optimizes the balance between reliability and cost.

How Predictive Maintenance Works

AI-powered predictive maintenance continuously monitors equipment through sensor networks measuring vibration, temperature, acoustic emissions, power consumption, pressure, and dozens of other parameters. Machine learning algorithms analyze these data streams in real-time, learning normal operating patterns for each asset. When measurements deviate from learned baselines, AI flags anomalies indicating developing problems. Advanced models correlate multiple signals to identify specific failure modes—bearing wear creates distinct vibration signatures, motor problems show characteristic power consumption patterns, and degrading seals produce unique acoustic signals.

The Data Foundation

Effective predictive maintenance requires comprehensive data collection. Accelerometers measure vibration in three axes, detecting imbalances, misalignments, and bearing defects. Thermal sensors track temperature at critical points, catching overheating from friction or electrical issues. Acoustic monitors detect ultrasonic frequencies from gas leaks, arcing, or friction. Current sensors identify electrical problems and motor degradation. Pressure transducers monitor hydraulic and pneumatic systems. Oil analysis sensors detect metal particles indicating wear. This sensor ecosystem creates a complete picture of equipment health impossible to achieve through periodic inspections.

Machine Learning Models

Several AI approaches power predictive maintenance systems. Anomaly detection algorithms learn normal behavior ranges and flag deviations without requiring labeled failure data. Supervised learning models trained on historical failure data recognize patterns preceding specific failure modes. Time series forecasting predicts when measurements will exceed critical thresholds. Classification algorithms diagnose specific problems from sensor patterns. Deep learning neural networks process complex signal combinations, identifying subtle patterns humans would miss. Ensemble methods combine multiple models for robust predictions across diverse equipment types.

Early Warning Systems

The true value of predictive maintenance lies in advance warning. Rather than detecting failures as they occur, AI identifies degradation weeks or months beforehand. A bearing showing early wear patterns might have three weeks of remaining life. This advance notice enables ordering replacement parts at standard prices, scheduling maintenance during planned downtime, and deploying technicians during regular shifts rather than premium overtime. Early intervention also prevents secondary damage—a failing bearing caught early prevents shaft damage, while a delayed failure destroys multiple components requiring extensive repairs.

Failure Mode Diagnosis

Beyond predicting when equipment will fail, AI diagnoses why. Vibration signatures distinguish bearing failures from shaft misalignment or belt issues. Power consumption patterns differentiate motor winding problems from mechanical binding. Temperature profiles identify cooling system failures versus overload conditions. This diagnostic capability enables targeted repairs rather than exploratory troubleshooting. Maintenance teams arrive with correct parts and knowledge, reducing repair time by 40-60% compared to reactive approaches where technicians must first diagnose problems before beginning repairs.

Optimizing Maintenance Schedules

AI enables condition-based maintenance that balances reliability with cost. Rather than replacing components on fixed schedules regardless of condition, or waiting for failures, systems optimize replacement timing based on actual wear. Components with remaining useful life continue operating, while those approaching critical states receive priority attention. This optimization typically reduces parts consumption by 20-30% while improving reliability. AI coordinates maintenance across equipment to consolidate downtime—if three machines need attention within the same timeframe, maintenance occurs simultaneously rather than in three separate shutdowns.

Integration with Manufacturing Systems

Predictive maintenance delivers maximum value when integrated with broader manufacturing operations. Links to production scheduling systems enable maintenance timing that minimizes production impact. Integration with inventory management ensures parts availability before needed. Connections to maintenance management systems automatically generate work orders when AI identifies issues. Links to asset management platforms track equipment history and maintenance costs. This holistic integration transforms maintenance from isolated activity into optimized element of overall manufacturing operations.

Real-Time Monitoring and Alerts

Modern predictive maintenance systems provide real-time visibility into equipment health through dashboards accessible on factory floors, in maintenance shops, and through mobile devices. Color-coded status indicators show at-a-glance equipment health across entire facilities. Automated alerts notify relevant personnel when conditions warrant attention, with escalation protocols ensuring critical issues receive immediate response. Historical trending reveals gradual degradation patterns while real-time monitoring catches sudden anomalies. This visibility enables proactive management rather than reactive firefighting.

Prescriptive Recommendations

Advanced systems go beyond prediction to prescription, recommending specific actions. When AI detects bearing wear, it suggests precise replacement timing based on production schedules, parts availability, and failure probability. Systems recommend optimal repair procedures based on failure mode diagnosis. AI balances multiple factors—failure risk, repair cost, production impact, parts availability—to optimize decisions. Over time, machine learning incorporates maintenance outcome data, continuously improving recommendations based on what worked previously.

Reducing Spare Parts Inventory

Predictive maintenance dramatically reduces required spare parts inventory. When equipment failures are unpredictable, manufacturers must stock extensive parts inventories to minimize downtime when failures occur. With advance warning of specific failures, parts can be ordered just-in-time for scheduled maintenance. This approach typically reduces spare parts inventory by 30-40% while simultaneously improving parts availability when needed. The working capital freed from excess inventory provides additional return on predictive maintenance investment.

Extending Equipment Life

Equipment often retires not because it's completely worn out, but because unexpected failures make it unreliable. Predictive maintenance enables operating equipment to its full useful life by preventing catastrophic failures that cause secondary damage. A motor with failing bearings, if repaired proactively, continues operating for years. If the bearing fails catastrophically, the resulting damage may require replacing the entire motor. This life extension provides substantial financial benefits, deferring capital expenditure on replacement equipment by years.

Energy Efficiency Benefits

Degrading equipment consumes more energy. Worn bearings increase friction, misaligned shafts waste power, dirty heat exchangers reduce efficiency, and aging motors draw excess current. Predictive maintenance catches these issues early, maintaining equipment at peak efficiency. Manufacturers implementing predictive maintenance often see energy consumption decrease 5-15% as equipment operates at designed efficiency levels rather than degraded states. In energy-intensive industries, these savings alone can justify predictive maintenance investment.

Quality Improvements

Equipment problems affect product quality before causing complete failures. Worn tooling produces parts outside tolerance. Degraded temperature control creates quality variation. Bearing problems introduce vibration affecting precision. By identifying and correcting equipment issues before they impact quality, predictive maintenance reduces defect rates by 10-30%. This quality improvement reduces scrap, rework, and warranty claims while improving customer satisfaction.

Safety Enhancements

Equipment failures create safety hazards. Exploding components, hot oil leaks, electrical arcing, and uncontrolled movements endanger workers. Predictive maintenance identifies safety-critical problems before they become hazardous, reducing workplace incidents. Regulatory compliance improves as maintenance records demonstrate proactive safety management. Insurance costs often decrease as insurers recognize reduced risk profiles.

Implementation Approaches

Successful predictive maintenance implementation follows phased approaches. Start with critical assets where downtime costs are highest—production bottlenecks, expensive equipment, or assets with poor reliability records. Deploy sensors and collect baseline data for several months before activating predictions, allowing models to learn normal patterns. Begin with simple anomaly detection before implementing complex diagnostic models. Demonstrate value on initial equipment before scaling across facilities. This measured approach builds organizational confidence and expertise while delivering early wins that fund broader deployment.

ROI and Business Case

Predictive maintenance ROI typically exceeds 5:1 within two years. Benefits include reduced unplanned downtime (40-50%), lower maintenance costs (25-30%), extended equipment life (20-40%), decreased inventory (30-40%), improved energy efficiency (5-15%), and better quality (10-30% defect reduction). For a mid-sized manufacturer, these benefits often total millions annually. Implementation costs including sensors, software, and integration typically payback within 6-18 months, making predictive maintenance one of manufacturing's highest-return technology investments.

Challenges and Considerations

Successful implementation requires overcoming several challenges. Legacy equipment may lack sensor mounting points or communication capabilities, requiring retrofit engineering. Data integration from diverse equipment types and protocols demands careful planning. Maintenance teams need training in new workflows and trusting AI recommendations. False positives early in deployment can erode confidence if not managed properly. Change management addressing cultural resistance to technology-driven maintenance proves critical. Organizations succeeding with predictive maintenance invest in training, communication, and demonstrating value rather than simply deploying technology.

The Future of Predictive Maintenance

Emerging technologies will enhance predictive maintenance capabilities. Digital twins—virtual equipment replicas—will enable simulating maintenance scenarios before physical implementation. Augmented reality will overlay maintenance guidance and equipment health data during repairs. Edge computing will enable faster processing and autonomous responses without cloud connectivity. 5G will support massive sensor deployments with minimal latency. Federated learning will allow models to improve across manufacturers without sharing proprietary data. Predictive maintenance will evolve toward truly autonomous systems that self-optimize and self-heal.

Conclusion

AI-powered predictive maintenance represents manufacturing's transition from reactive problem-solving to proactive optimization. By predicting failures before they occur, manufacturers minimize downtime, reduce costs, extend equipment life, and improve quality. The technology has matured from experimental to proven, with compelling ROI and manageable implementation paths. As manufacturing becomes increasingly competitive, predictive maintenance transitions from advantage to necessity. Equipment will either operate under AI-optimized maintenance regimes or face competitive disadvantage against facilities that do. The question is not whether to implement predictive maintenance, but how quickly to deploy it before competitors gain insurmountable efficiency advantages.